Before the holidays, one of our clients underwent an inspection by their local council, acting under FSA guidelines – https://www.food.gov.uk/ – and faced issues with missing mandatory labels on products. Discover what our client did and what steps you can take to always stay one step ahead of inspections.

Every grocery store owner in the UK knows how crucial it is to comply with the regulations. But what happens when a local council inspection, acting under FSA guidelines (https://www.food.gov.uk/), catches you off guard at the least convenient moment? Today, we’re sharing the story of one of our clients who faced such an inspection right before the holidays. The result? A few labelling shortcomings and clear recommendations from the inspector. Fortunately, the necessary adjustments were implemented quickly. Find out what our client did and what steps you can take to always stay one step ahead of inspections.

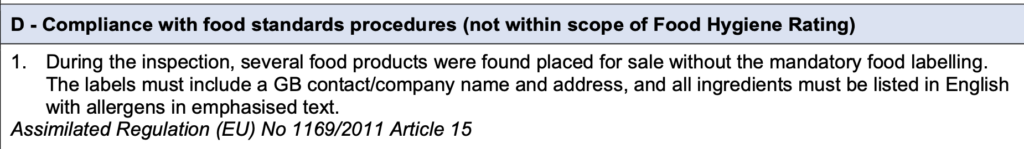

Before the holidays, one of our clients underwent an inspection carried out by their local council. The result? Some food products on the store shelves were missing mandatory labels. The inspector recommended implementing key changes in labelling:

This aligns with the requirements of Assimilated Regulation (EU) No 1169/2011, Article 15. This case served as a reminder of the importance of adhering to all phytosanitary requirements. Below are the specific recommendations given to the client:

Since 31 January 2024, the United Kingdom has introduced stricter regulations on the import of food products. These regulations affect all grocery stores, which must adapt to the new requirements. Here are the key changes:

The UK prioritises consumer safety, which is why product labelling must comply with regulations. Key requirements include:

Failure to comply with phytosanitary requirements and labelling regulations can lead to serious consequences:

Failure to meet the requirements constitutes a breach of food labelling and safety regulations, which may result in legal liability.

Incorrect allergen labelling can lead to severe allergic reactions, posing a risk to the health and lives of customers.

Regulatory authorities may impose substantial fines on shops that fail to meet the requirements.

Non-compliant products may need to be withdrawn from the market, resulting in additional costs and financial losses.

Non-compliance with regulations can deter customers and negatively impact the store’s image.

Documentation errors in imports can lead to goods being held at the borders, affecting delivery timelines.

To meet the requirements of the local council (acting under guidelines from https://www.food.gov.uk/) and avoid the consequences of incorrect food product labelling, grocery stores can utilise modern technological solutions that not only simplify compliance but also enhance operational efficiency. Here are detailed insights into two proposed solutions:

The price checker is an advanced device that, in addition to displaying product prices, includes built-in features to support compliance with labelling regulations.

How Does It Work?

Benefits for the Store:

Labeling Scales are specialized devices designed for fresh products such as meat, deli, and cheese. They combine the weighing function with automatic generation and printing of labels that comply with legal requirements.

Functionality:

Application:

Benefits for the Store:

By implementing price checkers and labeling scales, stores can significantly simplify the labelling processes, avoiding the risk of fines and financial losses. Both devices are intuitive to use and can be tailored to the specific needs of each store. It is also important to note the possibility of integration with other systems, which enhances store management efficiency.

New phytosanitary regulations and labelling requirements in the UK may seem complex, but with the right tools and collaboration with experienced suppliers, grocery stores can easily adapt to the changes. Adopting tools like labelling scales and price checkers with labelling functionality will help you comply with local council regulations, save time, reduce errors, and improve customer service quality. This allows you to focus on growing your business and building a competitive edge in the market. If you need support or have any questions, feel free to contact us!